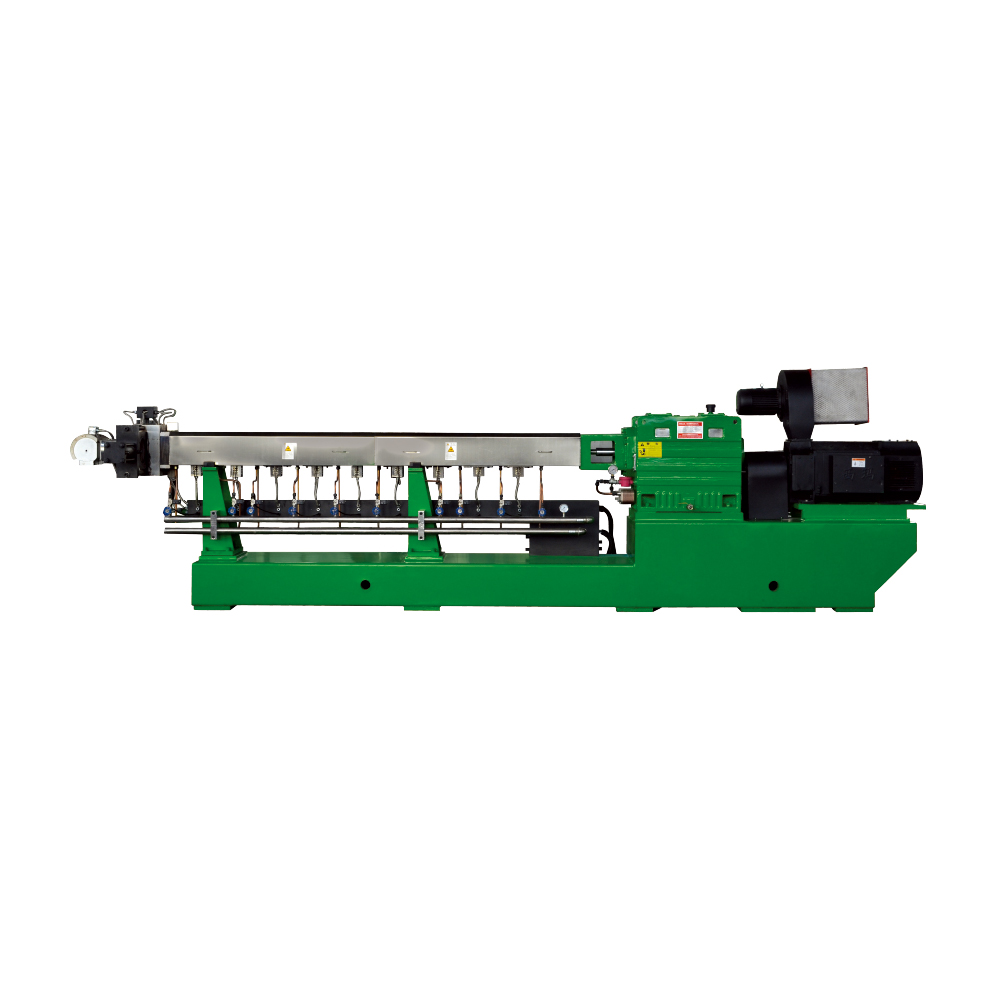

Tuam Tshoj Yas Extrusion Tshuab / Compounding / HDPE / PP / ABS / PS Twin Ntsia Hlau Extruder / Granulating Pelletizing Masterbatch Filling thiab Extruding Yas Extruder

Kev ua tiav ntawm cov neeg siv khoom yog peb lub hom phiaj tseem ceeb.Peb txhawb nqa ib qib kev tshaj lij, zoo tshaj plaws, kev ntseeg siab thiab kev pabcuam rau Quoted nqe rau Tuam Tshoj Yas Extrusion Tshuab / Compounding / HDPE / PP / ABS / PS Twin Ntsia Hlau Extruder / Granulating Pelletizing Masterbatch Filling thiab Extruding Yas Extruder, Peb lav zoo , yog tias cov neeg siv khoom tsis txaus siab ua ke nrog cov khoom zoo, koj tuaj yeem rov qab rau hauv 7 hnub nrog lawv cov thawj lub xeev.

Kev ua tiav ntawm cov neeg siv khoom yog peb lub hom phiaj tseem ceeb.Peb txhawb nqa ib qib zoo ib yam ntawm kev tshaj lij, zoo tshaj plaws, kev ntseeg siab thiab kev pabcuam rauTuam Tshoj Yas Extruder, yas tshuab, Kev tsim, ua, kev yuav khoom, tshuaj xyuas, khaws cia, sib dhos txheej txheem yog tag nrho hauv cov txheej txheem kev tshawb fawb thiab cov ntaub ntawv siv tau zoo, nce qib kev siv thiab kev ntseeg siab ntawm peb cov hom sib sib zog nqus, uas ua rau peb dhau los ua tus xa khoom zoo tshaj plaws ntawm plaub yam khoom loj pawg plhaub castings domestically thiab tau txais. tus neeg siv khoom ntseeg tau zoo.

TSSK series yog Co-rotating ob / Twin ntsia hlau extruder

Ntau lub zog gearbox, ntau cov ntsiab lus tseeb ntawm TSSK ua haujlwm tau yooj yim dua thiab ua haujlwm dav dua.Peb kuj muab cov kev daws teeb meem rau tus kheej raws li kev xav tau.Ntau yam ntawm modular ntsia hlau ntsiab, chim, yaj pom thiab pelletizing system yuav tau txais txiaj ntsig tshaj ntawm koj cov peev txheej.

Technical yam ntxwv:

Siab torque: Nqa peev xwm ntawm gearbox> = 13

High precision: Khiav-tawm qhov tseeb ntawm cov zis-ncej kom tas li, uas lav cov ntsia hlau me me tshem tawm

Lub neej kev pabcuam siab: Tsim kev pabcuam lub neej ntawm gearbox yog 72000hrs

Kev kub ceev: Max.1800rpm ib

High quality: me me clearance txo cov khoom to thiab rov qab-kawg, lub sij hawm nyob rau hauv tej kas tham thiab ntau shear.

Kev ua haujlwm siab: Cov zis yog 2-3 npaug ntau dua li qhov loj tib yam extruder los ntawm lwm cov tuam txhab hauv tsev.

Kev ua haujlwm yooj yim: PLC kov lub vijtsam nrog kev ua haujlwm meej meej, kev ua haujlwm yooj yim thiab yooj yim, ua ke nrog kev pabcuam tswj hwm ntawm kev sib tshuam.

Ntau hom kev ua cov ntaub ntawv: ntau yam ceev tuaj yeem ua tau raws li hom kev tsim cov khoom sib txawv, suav nrog cov khoom siv Crystalline, cov khoom siv zas xim, rub cov khoom siv.

Daim ntawv thov:

Kev hloov kho: caco3 / talcum hmoov / Tio2 / lwm yam inorganic muab tub lim

Kev hloov pauv yog siv rau hauv kev txhaj tshuaj, tshuab moulding, zaj duab xis (Ib txheej lossis Ntau txheej), daim ntawv thiab daim ntawv thov

Txhawb kev hloov kho: ntev lossis luv iav fiber ntau / carbon fiber

Kev npaj ntawm tus tswv batch: carbon dub master-batch / xim master batch / lwm yam tshwj xeeb functions master batch

Peb hom xim masterbatch:

1) Mono xim masterbatch lossis SPC (ib qho xim xim zoo nkauj): polymer compounding nrog ib qho xim thiab feem ntau tsis muaj cov quav thiab cov khoom ntxiv

2) Tailor-Made masterbatch lossis Custom coloring: sib tov sib txawv Mono xim masterbatch pellets kom tau cov xim uas tus neeg siv khoom xav tau

3) Customized masterbatch: sib xyaw polymer thiab ntau cov xim thiab cov khoom ntxiv

Blending kev hloov kho: cov khoom siv thermoplastic / Elastomer

Cov khoom siv cable: PVC cable khoom / Zero halogen cable khoom / khoom siv tshwj xeeb cable

Technical parameter:

| qauv | TSW-20 | TSW-30 | TSW-35 | TSW-50 | TSW-65 | TSW-72 | TSW-92 |

| Screw txoj kab uas hla (mm) | 21.7 ib | 30 | 35.6 ib | 50.5 ib | 62.4 ib | 71.2 ib | 91 |

| Rotary ceev (RPM) | 600 | 400 | 400/600 | 400/500 | 400/500 | 400/500 | 400/500 |

| Lub cev muaj zog (Kw) | 4 | 11 | 11/45 ib | 37/45 ib | 55/75 ib | 90/110 ib | 220/250 |

| L/D | 32-40 : kuv | 28-48 : kuv | 32-48 : kuv | 32-48 : kuv | 32-48 : kuv | 32-48 : kuv | 32-40 : kuv |

| Muaj peev xwm (Kg / H) | 2-10 | 5-30 | 10-80 | 20-150 | 100-300 | 300-600 | 600-1000 |

Kev ua tiav ntawm cov neeg siv khoom yog peb lub hom phiaj tseem ceeb.Peb txhawb nqa ib qib kev tshaj lij, zoo tshaj plaws, kev ntseeg siab thiab kev pabcuam rau Quoted nqe rau Tuam Tshoj Yas Extrusion Tshuab / Compounding / HDPE / PP / ABS / PS Twin Ntsia Hlau Extruder / Granulating Pelletizing Masterbatch Filling thiab Extruding Yas Extruder, Peb lav zoo , yog tias cov neeg siv khoom tsis txaus siab ua ke nrog cov khoom zoo, koj tuaj yeem rov qab rau hauv 7 hnub nrog lawv cov thawj lub xeev.

Quoted nqe rauTuam Tshoj Yas Extruder, Yas Machinery, Kev tsim, kev ua, kev yuav khoom, tshuaj xyuas, khaws cia, kev sib sau ua ke yog txhua yam hauv cov txheej txheem kev tshawb fawb thiab cov ntaub ntawv zoo, nce qib kev siv thiab kev ntseeg siab ntawm peb cov hom sib sib zog nqus, uas ua rau peb dhau los ua tus xa khoom zoo tshaj ntawm plaub yam khoom loj pawg plhaub castings. domestically thiab tau txais cov neeg siv khoom ntseeg tau zoo.

Lub tshuab yas rov siv dua thiab granulating yog ib hom khoom siv los siv cov khoom siv yas rov ua dua tshiab rau hauv granules lossis pellets uas tuaj yeem rov siv dua hauv kev tsim cov khoom yas tshiab.Lub tshuab feem ntau ua haujlwm los ntawm shredding los yog sib tsoo cov yas pov tseg rau hauv me me, ces melting thiab extruding nws los ntawm ib tug tuag los tsim pellets los yog granules.

Muaj ntau hom yas recycling thiab granulating tshuab muaj, nrog rau ib leeg-ntsia hlau thiab ntxaib-ntsia hlau extruders.Qee lub tshuab kuj suav nrog cov yam ntxwv ntxiv xws li cov ntxaij vab tshaus kom tshem tawm cov impurities ntawm cov khib nyiab yas lossis cov tshuab ua kom txias kom ntseeg tau tias cov pellets tau ruaj khov zoo.PET lub raj mis ntxhua khaub ncaws, PP woven hnab ntxhua khaub ncaws

Plastic recycling thiab granulating tshuab feem ntau yog siv rau hauv kev lag luam uas tsim cov khoom pov tseg yas ntau, xws li ntim, tsheb, thiab kev tsim kho.Los ntawm kev rov ua dua cov pov tseg yas, cov tshuab no pab txo qis ib puag ncig kev cuam tshuam ntawm cov yas pov tseg thiab txuag cov peev txheej los ntawm kev rov siv cov ntaub ntawv uas yuav muab pov tseg.

Cov cuab yeej siv roj teeb lithium yog ib hom khoom siv los siv rov ua dua thiab rov qab cov ntaub ntawv tseem ceeb los ntawm cov roj teeb lithium-ion, uas feem ntau siv hauv cov khoom siv hluav taws xob xws li smartphones, laptops, thiab tsheb fais fab.Cov cuab yeej siv feem ntau ua haujlwm los ntawm kev rhuav tshem cov roj teeb rau hauv lawv cov khoom siv, xws li cov khoom siv cathode thiab anode, cov tshuaj electrolyte, thiab hlau foils, thiab tom qab ntawd sib cais thiab ntxuav cov ntaub ntawv no rov qab siv dua.

Muaj ntau hom lithium roj teeb rov siv dua cov cuab yeej muaj, suav nrog cov txheej txheem pyrometallurgical, cov txheej txheem hydrometallurgical, thiab cov txheej txheem siv tshuab.Cov txheej txheem Pyrometallurgical koom nrog kev ua haujlwm kub ntawm cov roj teeb kom rov qab tau cov hlau xws li tooj liab, npib tsib xee, thiab cobalt.Cov txheej txheem Hydrometallurgical siv cov tshuaj daws teeb meem kom yaj cov roj teeb thiab cov hlau rov qab, thaum cov txheej txheem tshuab muaj kev sib tsoo thiab milling cov roj teeb kom cais cov ntaub ntawv.

Cov khoom siv roj teeb lithium rov ua dua yog qhov tseem ceeb rau kev txo qis ib puag ncig kev cuam tshuam ntawm cov roj teeb pov tseg thiab txuag cov peev txheej los ntawm kev rov ua kom muaj txiaj ntsig zoo thiab cov khoom siv uas tuaj yeem rov qab siv tau hauv cov roj teeb tshiab lossis lwm yam khoom.

Ntxiv rau cov txiaj ntsig kev txuag ib puag ncig thiab kev txuag, cov khoom siv roj teeb lithium kuj tseem muaj txiaj ntsig kev lag luam.Rov qab tau cov khoom muaj txiaj ntsig zoo thiab cov khoom siv los ntawm cov roj teeb uas siv tau tuaj yeem txo tus nqi ntawm kev tsim cov roj teeb tshiab, nrog rau tsim cov nyiaj tau los tshiab rau cov tuam txhab koom nrog hauv cov txheej txheem rov ua dua tshiab.

Tsis tas li ntawd, qhov kev thov nce ntxiv rau lub tsheb hluav taws xob thiab lwm yam khoom siv hluav taws xob yog tsav qhov kev xav tau rau kev lag luam roj teeb uas muaj txiaj ntsig zoo dua thiab muaj txiaj ntsig zoo.Cov cuab yeej siv roj teeb lithium tuaj yeem pab ua kom tau raws li qhov kev thov no los ntawm kev muab txoj hauv kev txhim khu kev qha thiab raug nqi kom rov qab tau cov ntaub ntawv tseem ceeb los ntawm cov roj teeb siv.

Txawm li cas los xij, nws tseem ceeb heev uas yuav tsum nco ntsoov tias kev rov ua dua lithium roj teeb tseem yog ib qho kev lag luam tshiab, thiab muaj cov kev sib tw kom dhau los ntawm kev tsim cov txheej txheem rov ua tau zoo thiab raug nqi.Tsis tas li ntawd, kev tuav thiab pov tseg cov roj teeb pov tseg yog qhov tseem ceeb kom tsis txhob muaj kev phom sij rau ib puag ncig thiab kev noj qab haus huv.Yog li ntawd, cov kev cai tsim nyog thiab kev ntsuas kev nyab xeeb yuav tsum nyob rau hauv qhov chaw los xyuas kom meej lub luag haujlwm tuav thiab rov ua dua lithium roj teeb.